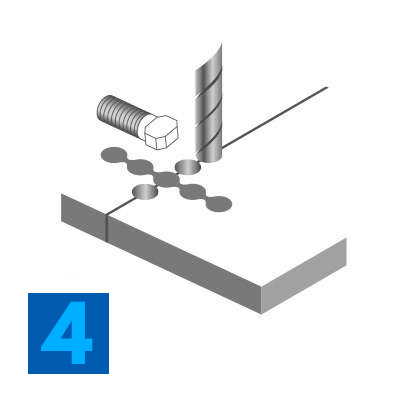

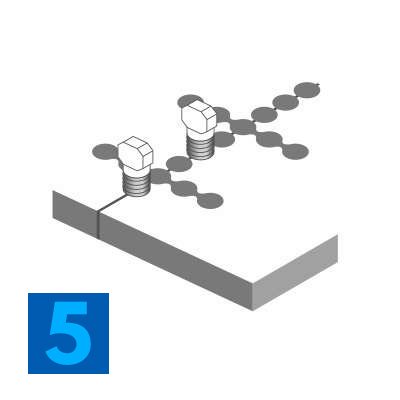

The Metalock process, known as metal stitching, is a unique rapid and permanent method for repairing cracks or for joining pieces of broken cast metal components without welding.

Cold casting repairs carried out by Metalock International Association (MIA) members are superior to welding in the case of crack-sensitive metal. The repairs can take place in otherwise hazardous conditions for welding and cause minimal disruption to operations.

Each repair only requires equipment that can be carried by hand and is generally completed in a matter of days and can typically restore the strength of the equipment so that it will continue to operate to full specifications.